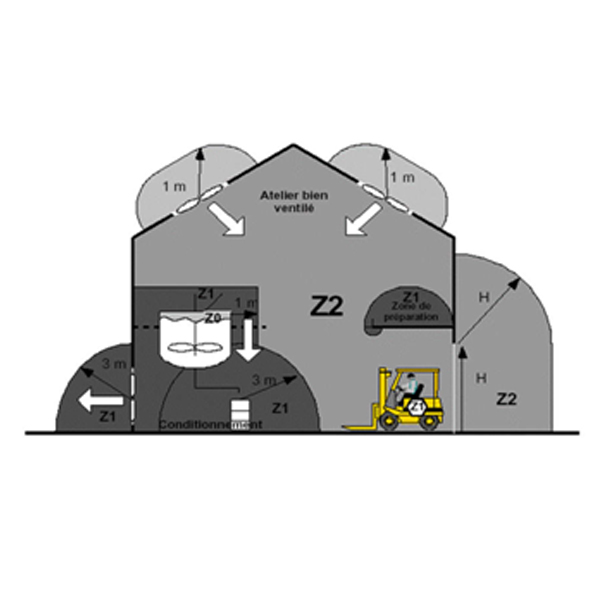

Zonage ATEX pour identifier les dangers, mettre en place les équipements nécessaires et optimiser la sécurité de votre site

Réaliser des inspections de vos centres de production et de vos équipements de manière à garantir leur conformité

Zonage ATEX pour identifier les dangers, mettre en place les équipements nécessaires et optimiser la sécurité de votre site

|

Score |

Notes |

||

|

Areaclassification |

|||

|

Zone0 |

15points |

Or |

|

|

Zone1 |

10points |

Or |

|

|

Zone2 |

5points |

Or |

|

|

Unclassified |

1point |

Non-Hazardous |

|

|

Environmentalconditions |

|||

|

OutdoorExtreme |

5points |

Exposed to weather elements (water, |

|

|

OutdoorModerate |

3points |

Near |

|

|

Indoor |

1point |

Dry, |

|

|

Corrosion |

|||

|

High |

4points |

Delaminating |

|

|

Medium |

2points |

Degraded |

|

|

Low |

1point |

Light |

|

|

Vibration |

|||

|

High |

4points |

Rotating |

|

|

Medium |

2points |

Flow/process |

|

|

Low |

1point |

Equipment |

|

|

Historical |

|||

|

High |

4points |

More |

|

|

Medium |

2points |

1 |

|

|

Low |

1point |

No |

|

|

Historical |

|||

|

High |

4points |

Multiple |

|

|

Medium |

2points |

1 |

|

|

Low |

1point |

No |

|

|

|

|||

|

Totalpoints |

——————————————————————————————— |

||